So...

Once upon a time I came to a conclusion that there's a need to reball a PS3 console. Customer brought a 60GB YLOD console which was attempted to be fixed before. After the first reflow console came alive and worked for around couple minutes, then died again with Red Blinking Light. While reflowing for the second time I used some high quality flux. After reflow the same scenario, came alive, turned it off and it came back with Red Blinking Light.

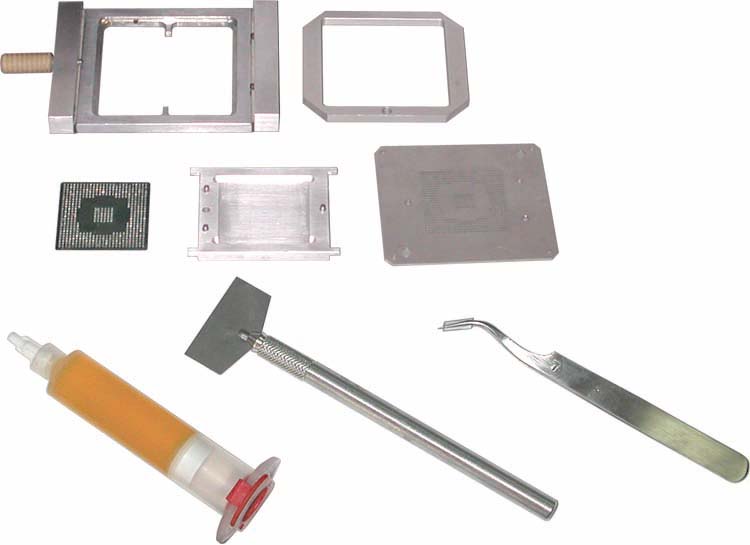

The reball was the only solution, so I cranked up my JOVY switched on the Aoyue and with not much enthusiasm the reball process was started.

Here are some pics how I got on.

Once the heatsink came off at 140C the RSX was lifted without much effort.

The residue left from earlier reflows.

Close up of overburned flux.

The RSX ready to be cleaned.

While cleaning the chip the coating has come off in couple places.

I called this chip faulty and binned it.

However the motherboard cleaned up pretty nicely, some effort was required though.

60GB motherboard is massive.

Close up of perfectly clean RSX chip motherboard spot.

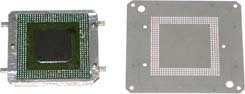

The new chip came to the rescue. Also removed from 60Gb motherboard.

Reballed using Aoyue 968 and 0.6mm leaded solder balls.

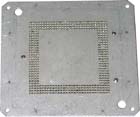

The reballing jig of eBay is very poor quality.

Admiring the masterpiece.

All the solder balls aligned perfectly.

RSX heatsink cleaned up from old thermal paste and ready to go back on.

The board went under JOVY and everyting seem to be fine.

Heatsink went back on using new thermal paste and Arctic Silver Ceramique on RSX Ram.

tukar chipset dengan harga rm 400

BalasPadamjika laptop anda tiada display dll